https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.

https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.From light simulation to the finished product

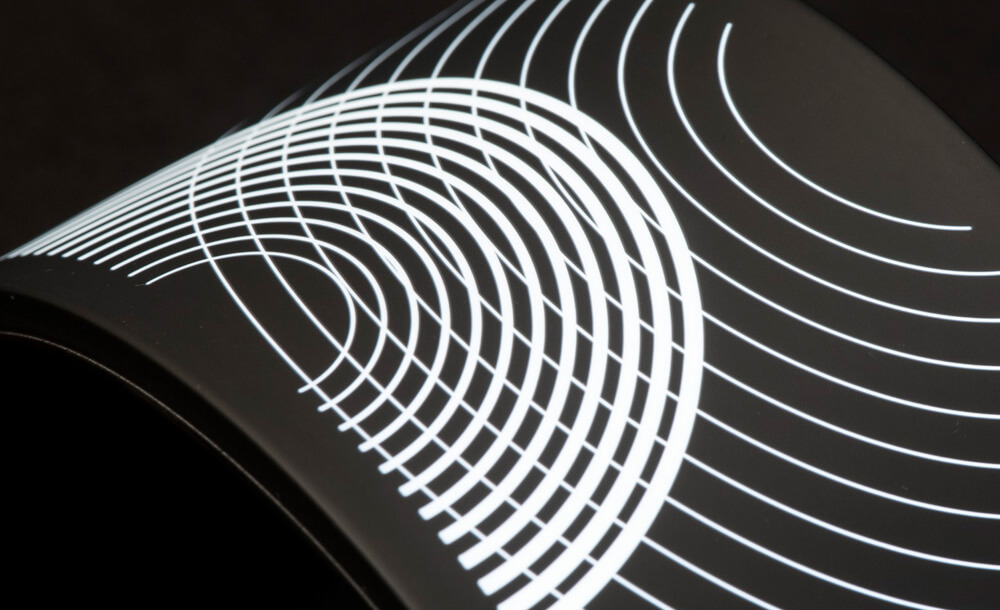

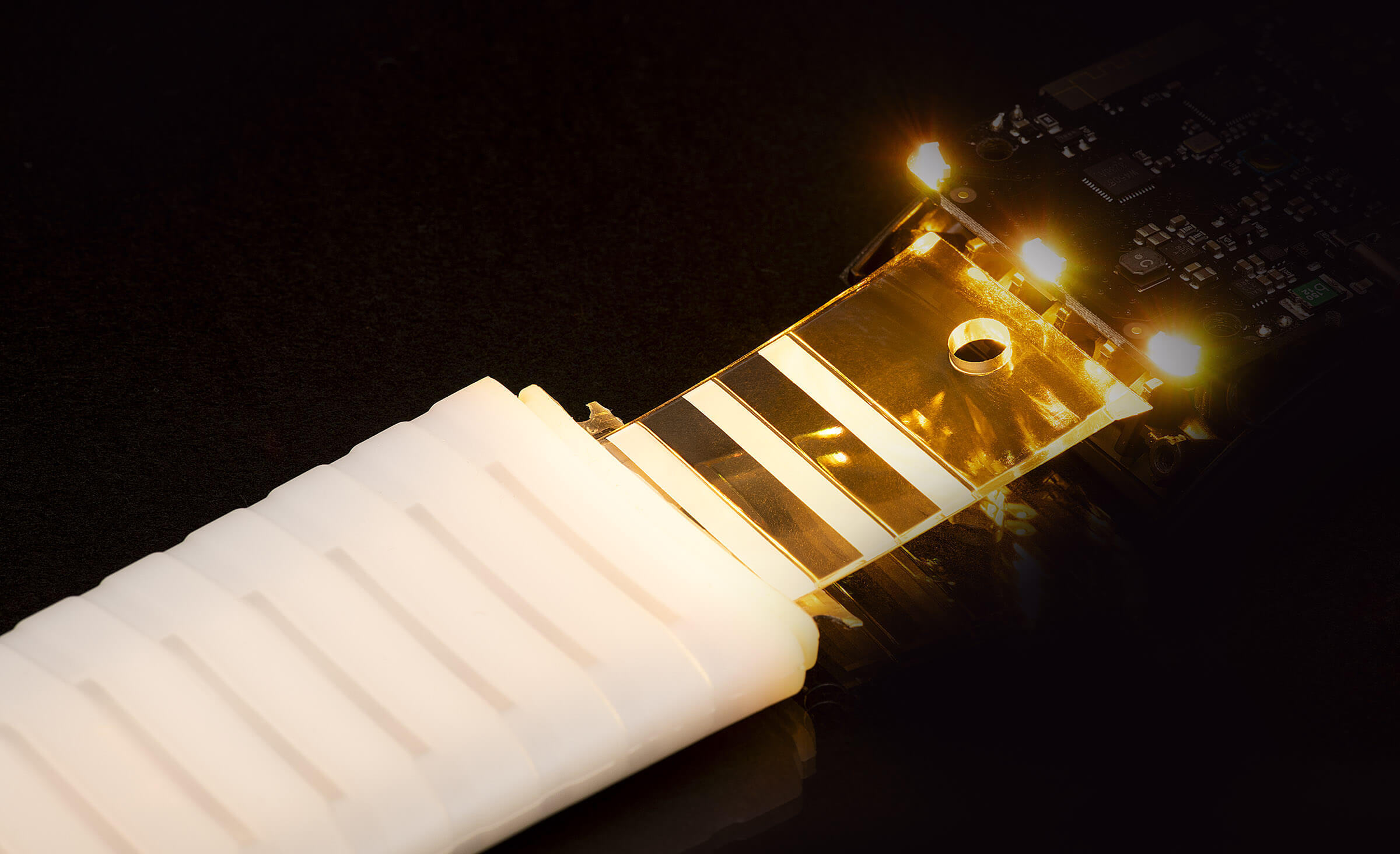

Silicone moulded parts made of optical silicone have the optical clarity of glass, but are lighter than glass or thermoplastics. Silicone also has better haze and dispersion properties than comparable plastic materials such as PC or PMMA.

In addition to its unique material flexibility, optical silicone has long-term temperature resistance up to 150°C and low-temperature flexibility down to -50°C. It is also characterised by high resistance to chemicals and weathering, while its UV stability prevents the components from yellowing.

At a glance – The advantages of silicone moulded parts for optical applications

- Optical clarity

- Flexibility

- High long-term temperature resistance

- Cold flexibility

- UV stability

- High transmission

- High resistance to chemicals and weathering

Silicone moulded parts for optical applications

Discover our product range and download our comprehensive data sheet to find out more about our high-quality silicone moulded parts.

Perfect use in optical applications

Thanks to their unbeatable properties, silicone materials are suitable for a wide range of applications, such as the production of complex and very precise geometries and microstructures.

- For applications with limited space

- At high temperatures due to high-performance LEDs or xenon lamps

- For the shading of certain areas of the optical components

- For decorations using printing, spray painting or PVD coatings

- For protection against dirt build-up on secondary optics

A business worth millions.

The design process involves the precise coordination of colours, materials and surfaces to create functional and aesthetic products. Careful selection and innovative techniques are used to create surfaces that both strengthen the brand identity and influence perception and the user experience.