https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.

https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.Digital printing on a flexible silicone surface

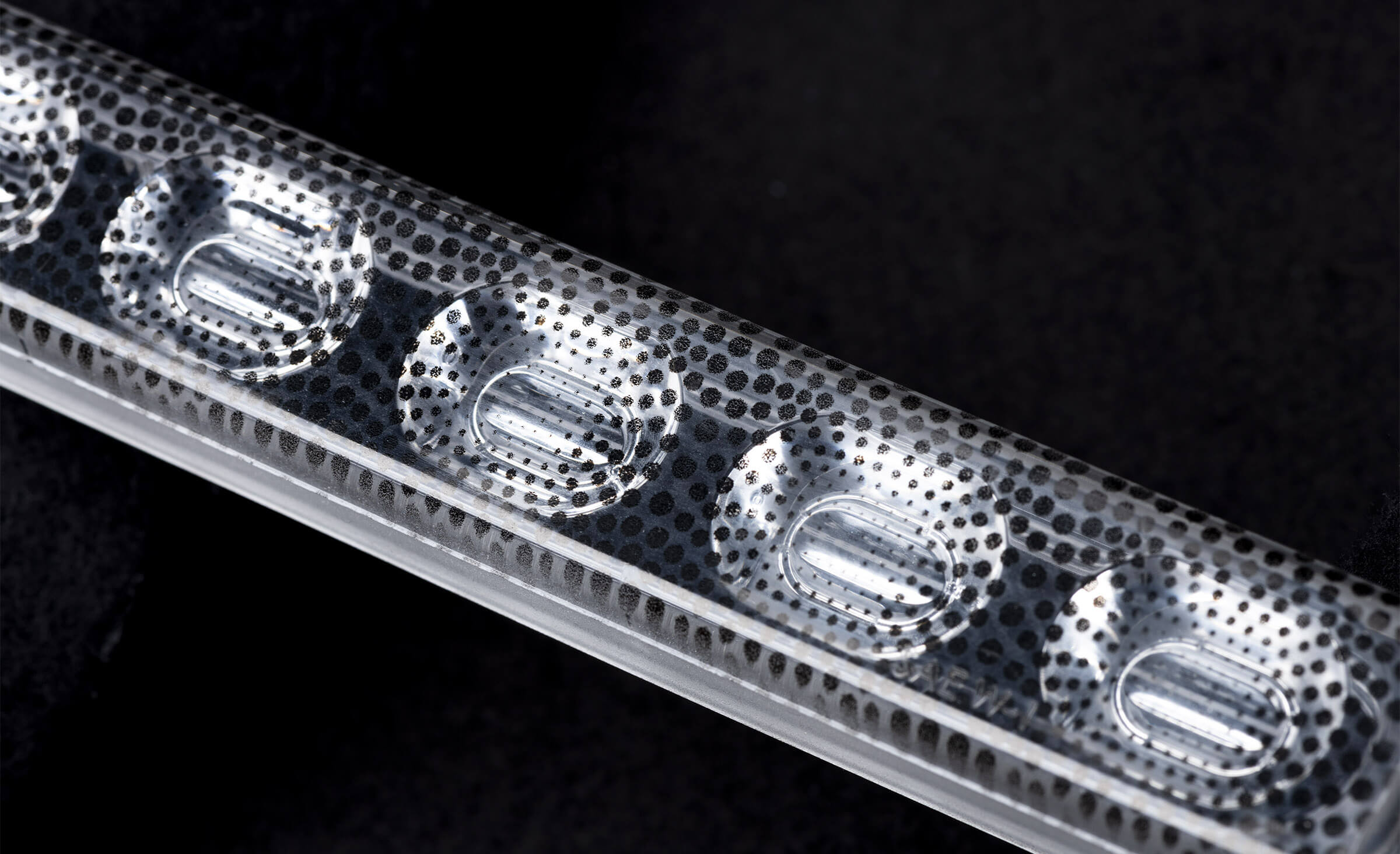

Photorealistic printing on flexible silicone surfaces. The flexibility and ductility of the component should not be impaired as much as possible.

After printing, the moulded part should be robust in use, scratch and abrasion resistant and resistant to chemicals, cleaning agents and water.

Your task

- High-quality look and feel

- Several colours in one printing process

- Lot size 1

- Processing of digital data such as photos, logos, texts and images

- Robust in use, with mechanical abrasion resistance

- Resistant to water and cleaning agents

Customised silicone solutions

Basic requirement for data:

- Resolution of photos: at least 150 dpi (300 dpi in final format is best)

- file format for logos and graphics: delivery as vector graphics if possible

Digital printing is the ideal way to print your silicone moulded parts individually down to a batch size of 1. The process enables full-surface printing in “true colour” quality and direct processing of digital artwork – there is no need to invest in printing plates, screens or pads.

After printing, we apply a highly abrasion-resistant and flexible protective coating to the silicone surface. On request, we can also integrate search and function lighting on the printed silicone surfaces.

Our implementation

- Direct processing of digital artwork (e.g. photos, logos, text and images) – no need to invest in printing plates, screens or pads

- White, flat silicone moulding as a base

- Digital industrial printing process for full-surface printing in “true-colour” quality

- Maintenance of the flexibility of the base material

- Customisation options

- Can be combined with homogeneous fibre-optics from siloptics® Flexilight

Finishing through printing and laser marking

Discover our product range and download our comprehensive data sheet to find out more about our finishing processes.

Our summary

Multi-coloured, solid and durable

With digital printing, we meet all the requirements for your customised printed silicone moulded parts: impressive quality, multiple colours in a single printing process and direct processing of digital data. Once printed, the moulded part is also robust in use, scratch and abrasion resistant and resistant to chemicals, cleaning agents and water.

A business worth millions.

The design process involves the precise coordination of colours, materials and surfaces to create functional and aesthetic products. Careful selection and innovative techniques are used to create surfaces that both strengthen the brand identity and influence perception and the user experience.