https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.

https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.Realistic 3D depth effect in transparent components

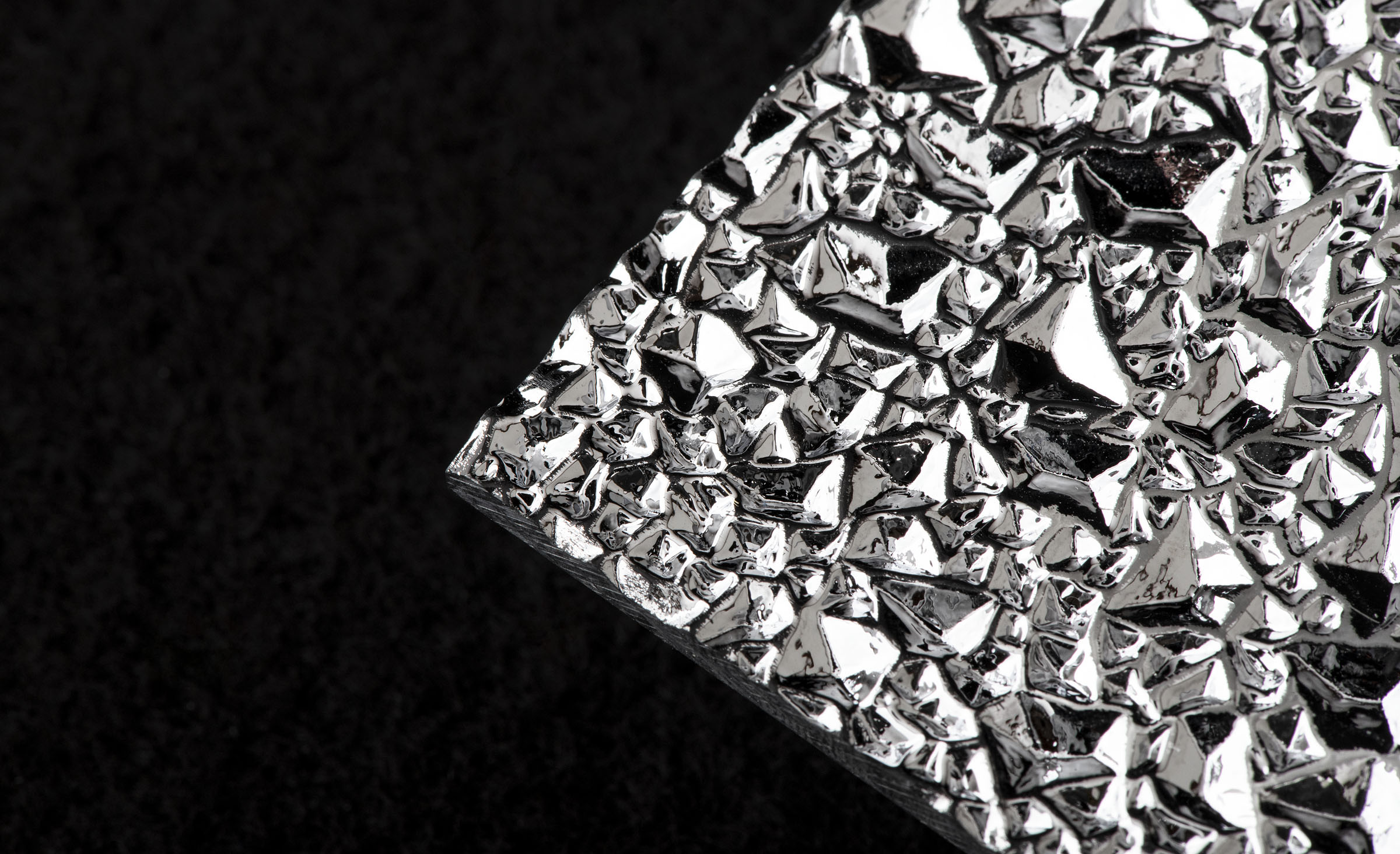

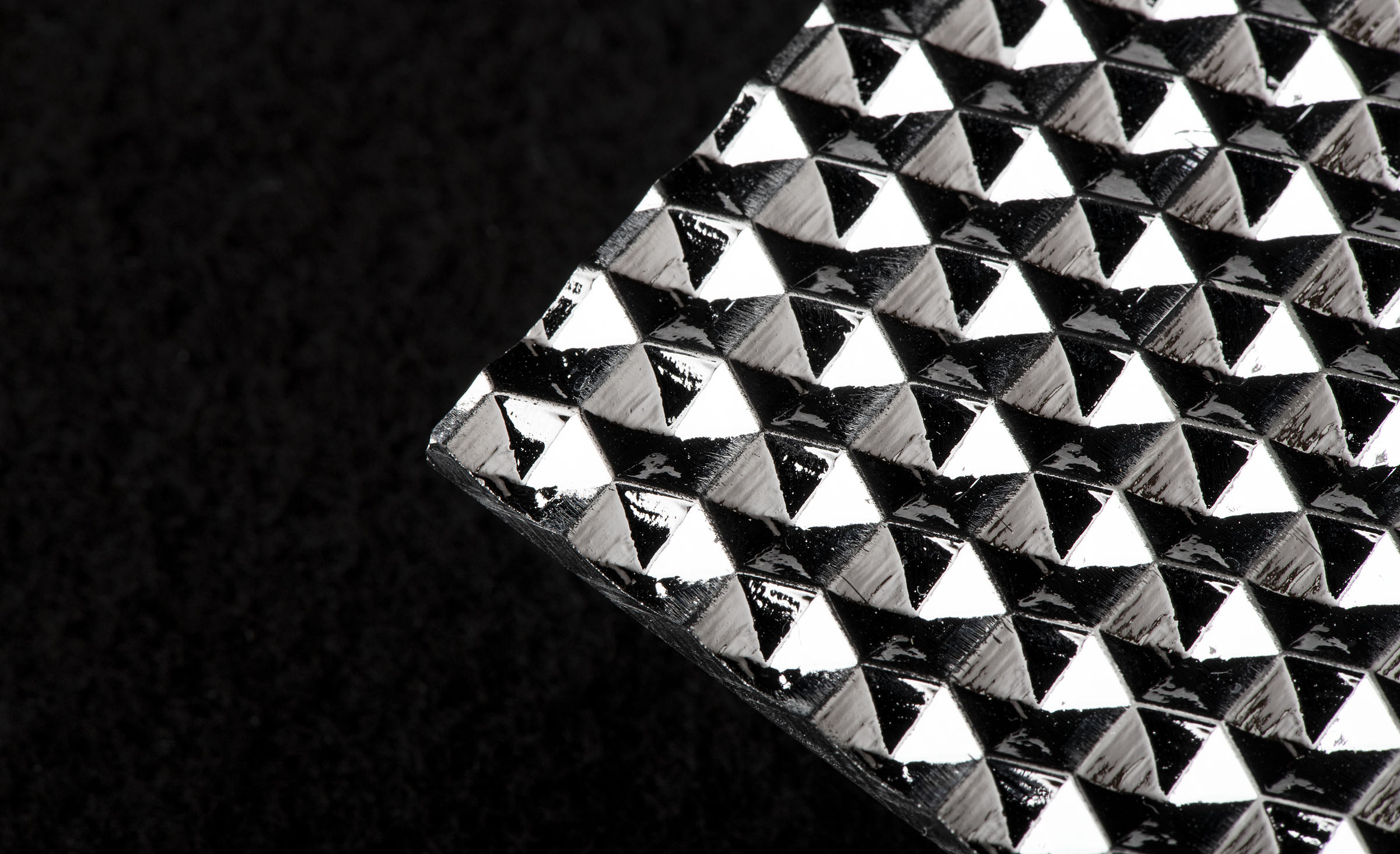

Applications on switches and steering wheel covers with three-dimensional inserts create real highlights in the vehicle interior, but were previously complex and expensive or even impossible to realise.

The task involved the creation of keycaps with a glass look, a three-dimensional logo and a multi-coloured background. In addition, functional lighting is to be integrated in the disappearing effect and the entire component is to be able to withstand the harsh environmental conditions – without the need for a protective cover. For example, rough conditions in trousers and handbags pose a major challenge for decorative surface finishes on vehicle keys.

Your task

- Excellent visual and tactile appeal

- Highly abrasion and scratch resistant

- Temperature range from -40°C to +90°C

- Chemical resistance

- UV resistance

Our implementation

We have combined various existing technologies into a new process to create a truly realistic 3D depth effect in transparent plastic components made of polycarbonate, silicone or Plexiglas.

The solution consists of an optimally coordinated combination of injection moulding with different printing and laser processes and metallisation with Siloptics® PVD on the back of the component. The extremely high abrasion and scratch resistance is achieved by applying a state-of-the-art UV protective coating system to the front of the component. We produce your component in such a way that it fulfils the specific requirements of various sectors such as the automotive and consumer goods industries, white goods, life sciences, etc. in terms of temperature range, abrasion and scratch resistance, chemical resistance and UV resistance.

We achieve the visual highlight of the 3D depth effect by combining existing technologies.

- Highly abrasion-resistant protective surface coating

- Real metal coating with silmade® PVD

- Temperature-resistant over a wide range

- Resistant to UV radiation and chemicals

- Full 3D design freedom

Our summary

Our technologies for the production of three-dimensional structures and geometries are an efficient and cost-effective option with added value, especially for use in premium products.

Which of your polycarbonate, silicone or Plexiglas components can we help to achieve an absolutely realistic 3D depth effect with our siloptics® technologies next?

A business worth millions.

The design process involves the precise coordination of colours, materials and surfaces to create functional and aesthetic products. Careful selection and innovative techniques are used to create surfaces that both strengthen the brand identity and influence perception and the user experience.