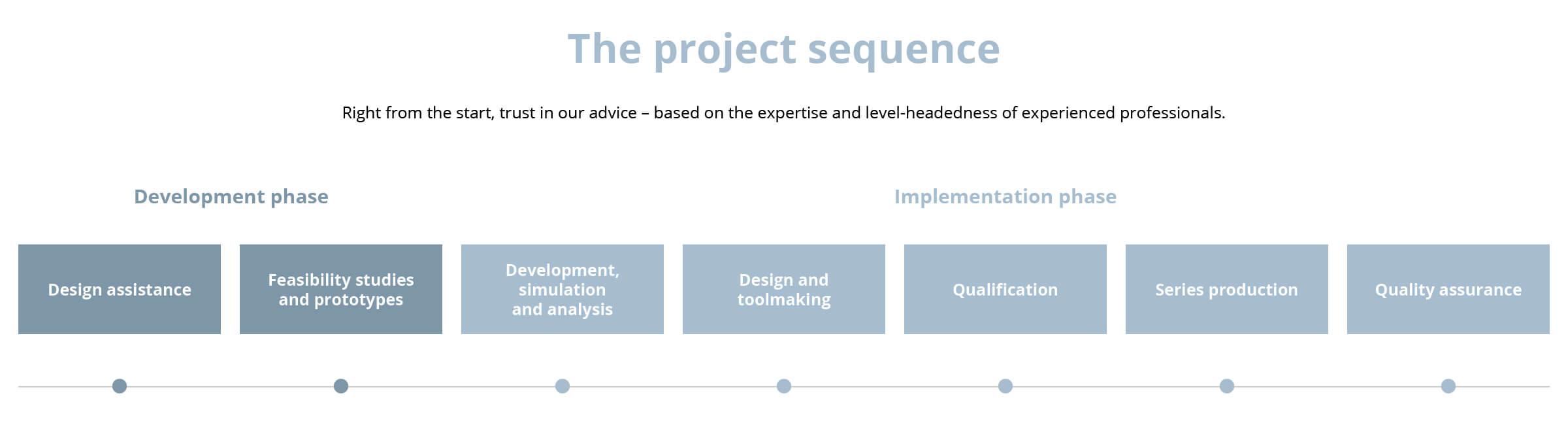

Target-orientated and efficient

Our experts provide you with an all-round service from the design and conception phase to the final finish in order to realise your project in the best possible way. In order for your component to survive in series production and be a success, it is a great advantage to define all the important specifications right from the start. At Silcos, we work with you to make the right choice for the surface coating right from the discovery phase and accompany you with our professional service all the way to the completion of your product.

The first step to a successful customer project

For us, consulting means supporting our customers in all project phases with comprehensive information and expertise. This is invaluable for making decisions or improvements.

From the idea to the finished component

Silcos acts as a system provider and manages products from the task definition to the production of a prototype through to series production. For us, consulting means supporting our customers in all project phases with comprehensive information and expertise. This is invaluable for making decisions or improvements.

Feasibility studies

Silcos tests production processes and refinements in a quick and agile manner.

As part of a feasibility study, we examine various solution approaches for your project with regard to their feasibility, i.e. whether we can fulfil the agreed project results (component geometries, coating areas, compliance with specifications, etc.) under the given framework conditions with the respective solution approach. We identify risks and assess the prospects of success of your project.

Goals

- Identification of the best solution

- Assessment of potential risks

- Prevention of bad investments

- Recommendation for a decision

Development, simulation and analysis

Your projects are sure to take shape here

We develop, simulate and analyse products specifically in line with our customers’ ideas and wishes. We use state-of-the-art tools, e.g. for mould flow analyses, light calculations or light simulation, statistical test planning.

Rely on Silcos – we help you to realise your vision economically and reproducibly.

- Early design assessment

- Support for product development and tool design

- Early mould optimisation through injection moulding simulation

- Valuable cost and time savings

- Compliance with time-to-market targets

Prototypes and sample construction

From the idea to series production in the shortest possible time

Prototypes help to transform abstract ideas into tangible models.

Based on existing components, prototypes can be flexibly provided with new surfaces at any time as feasibility studies. This allows us to quickly find the right technologies and, if necessary, develop new processes to fulfil your customer-specific requirements.

Advantages

- Product properties can be checked at an early stage

- Test samples are available at an early stage

- Near-series models (illustrative and functional models)

- Early design assessment

Design and toolmaking

Thanks to our in-house design department with modern 3D CAD workstations, you receive your virtual models as a basis for optimised product design.

We design the tools required for your products according to your specifications and develop the equipment for the surface finishing processes.

Depending on the requirements and type of mould, these are manufactured by international partners and qualified by us.

Qualification

Do the parts meet your requirements?

Before series production can start, it must be ensured that the products meet customer requirements.

The corresponding tests and scope of sampling are primarily dependent on the industry and application. Industry standards such as PPAP, VDA 2 or OQ and PQ are our daily bread.

We use internal and external accredited test laboratories for validation.

Serial production

Highest quality in the series process

High-quality tools and production systems and an optimised and stable production process are essential for manufacturing high-quality products. The series shows how the findings on simulation and prototypes were moulded in a perfect process.

Quality assurance

Your product in the best hands

The extensive in-house testing equipment guarantees regular, permanent quality testing.

The integrated and certified management systems for quality according to IATF-16949 and ISO 9001, for the environment according to ISO 14001 and energy according to ISO50001 are key for implementing your requirements.