https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.

https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.The secret to metallic surfaces on plastic

Metallic-looking surfaces are in great demand in many industries.

Silcos has the perfect answer: Physical Vapour Deposition, or siloptics® PVD for short, is a decorative and functional technology for applying wafer-thin metal layers to a wide variety of plastics and even flexible materials.

Your advantages

- visually brilliant

- environmentally compatible

- additional functionality

- established in series production

- everything from a single source

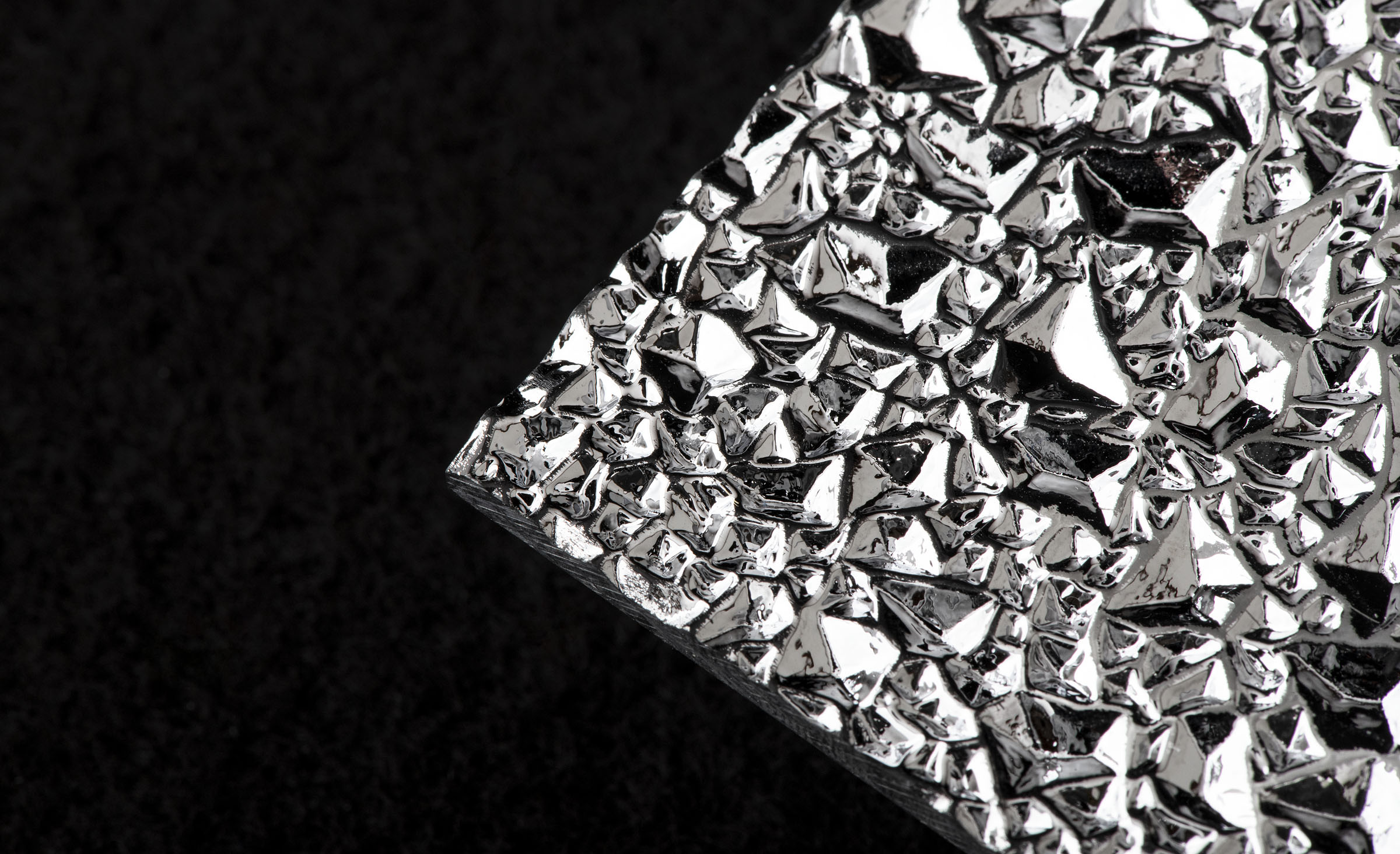

Visually appealing metal surfaces

The coating process is based on the physical principle of cathode sputtering with magnetic field support, which is known as “magnetron sputtering”. Ion bombardment is used to transfer metal atoms from a solid metal plate into the gas phase and then deposit them on the components. The PVD surface is given a protective layer of lacquer for a brilliant finish. This process is fully automated and completely reliable in terms of variations in colour tone and layer thickness.

Our siloptics® PVD technology provides many highlights, especially in the aesthetics-orientated automotive industry.

As a pioneer in PVD, we have been metallising your plastic parts without chromium (VI) in series production since 2006.

Discover our product range and download our comprehensive data sheet to find out more about the possible applications of siloptics® PVD technology.

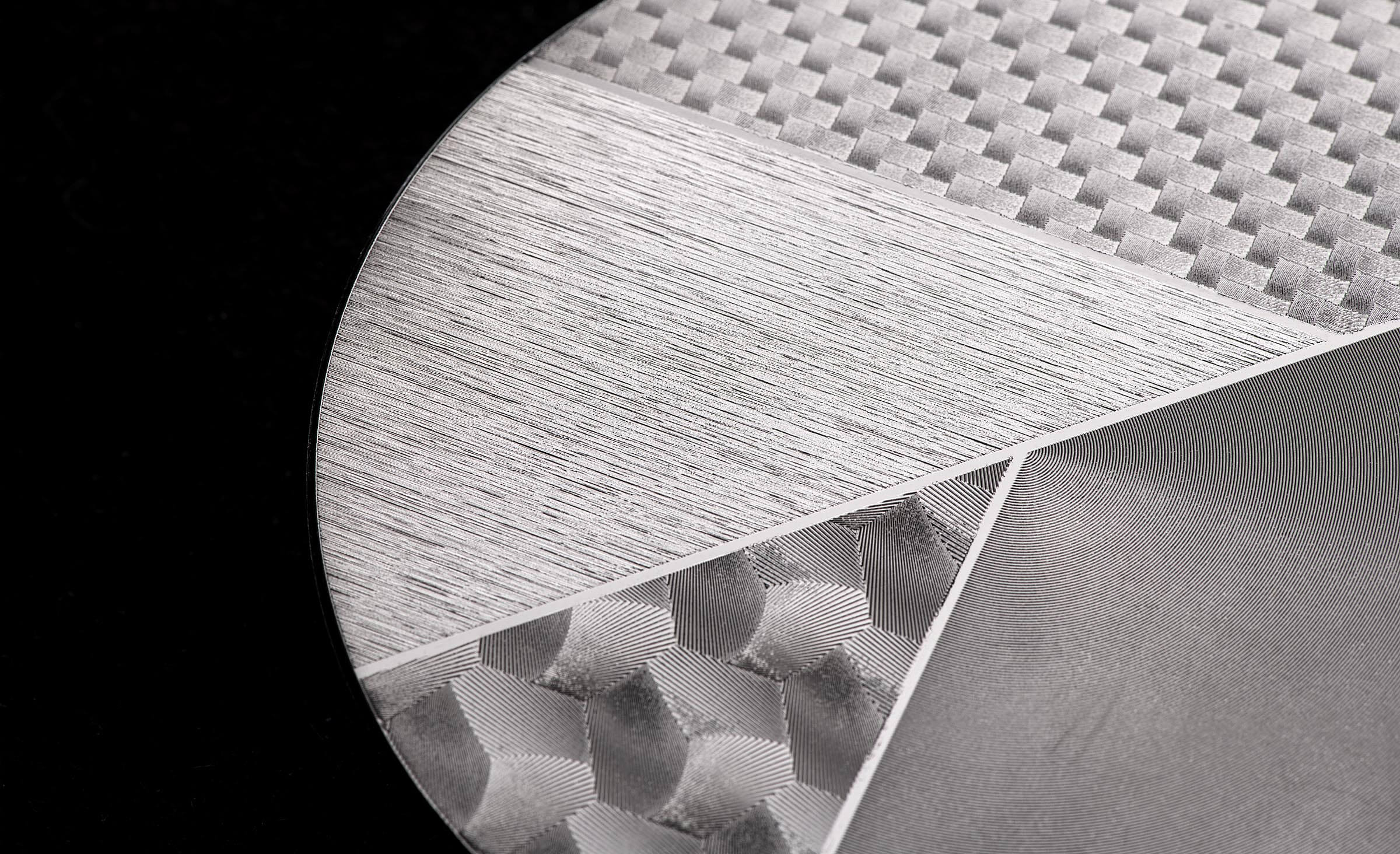

Flawless metal surfaces

Metallisation of plastic

Day-night design

Backlit characters and symbols can be displayed as required using laser marking and are used for switch applications, for example.

Translucency

Semi-transparent PVD coatings can be used to illuminate metallic surfaces – with the keyword here being the disappearing effect.

Splinter-free and flexible

Due to the flexibility of the material, PVD is suitable for many different and soft materials, e.g. for safety-relevant components such as decorative elements on airbag covers.

Variable conductivity

The electrical conductivity of PVD coatings is adjustable, making it possible to produce radar-transparent or non-radio-shielding surfaces – even in combination with capacitive sensors.

A business worth millions.

The design process involves the precise coordination of colours, materials and surfaces to create functional and aesthetic products. Careful selection and innovative techniques are used to create surfaces that both strengthen the brand identity and influence perception and the user experience.