https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.

https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.High-quality look combined with functionality

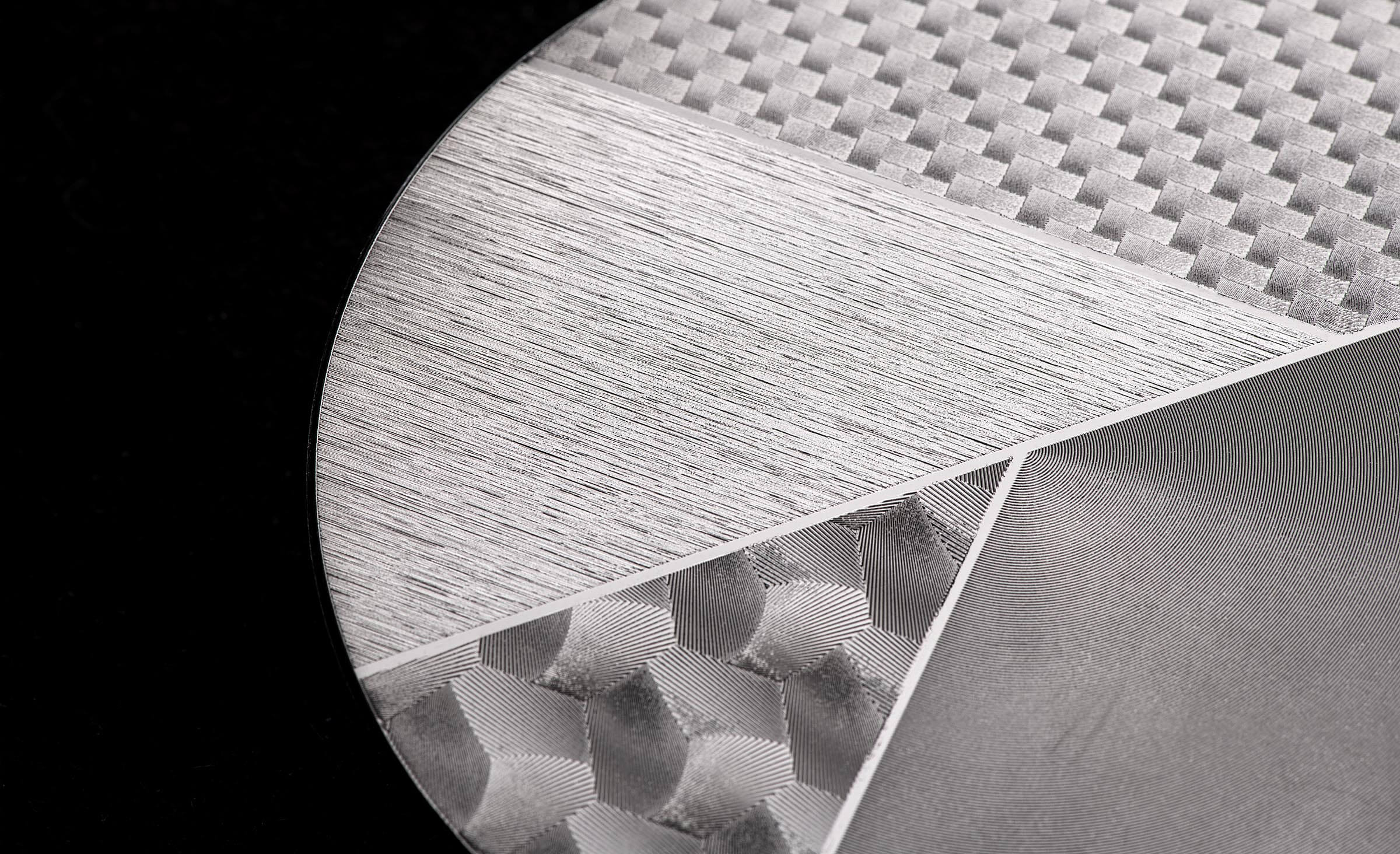

Using innovative coating systems developed especially for our customers, we coat plastic parts for many well-known manufacturers in medium and large series on a daily basis to the highest quality standards. Our plant is equipped for both 2D and 3D coatings. This not only guarantees aesthetically pleasing results, but also reliable protection.

Desired properties such as high scratch and abrasion resistance or a special feel are taken into account, as is a sophisticated appearance. We influence the gloss level of the component or surface by modifying the protective coating. This allows us to create surfaces ranging from high gloss and silk matt to matt.

Prior surface treatment and a coating process customised to the requirements ensure a long-lasting and optimum result.

Our coatings

- Piano lacquer for high-closs plastic surfaces

- Anti-scratch coatings for maximum resistance

- Chrome-effect lacquers for matt chrome looks

- also in combination with printing and laser making

Coating of plastic parts

At Silcos, the fulfilment of your specific requirements takes centre stage. We specialise in the processing of high-quality special and effect coatings on demanding surfaces and our portfolio ranges from the processing of thermally curing coatings to the latest generation of mono- and dual-cure UV coating systems. These coatings come from various manufacturers and are carefully selected to meet your individual customer specifications and applications.

The tool and injection moulding are subject to the highest requirements, as the smallest defects are immediately visible due to the degree of gloss. In addition to the injection mould, cleanliness during production is a key criterion throughout the entire process. We produce components from development and mould construction to series production in clean rooms.

- Overview of the entire process chain

- Designed for complex 2k and UV coating systems

- Depending on the component geometry, modern, fully automated flatbed, spindel and robot coating systems

- Maximum yield of flawless good parts thanks to high cleanliness along the value chain

Coating of plastic parts

Find out more about our innovative coating systems for high-quality, resistant plastic surfaces and download our comprehensive data sheet.

Coating with chrome-effect lacquers

As an alternative to the PVD process, we use our chrome-effect lacquers, which we have developed over the years to create high-quality satin matt, metallic-looking surfaces on plastic parts.

- The result depends on the number of coats (with 1-3 coats of lacquer).

- The high-quality and hard-wearing surfaces are comparable with those from PVD technology.

- Chrome-effect lacquers are suitable for almost all materials.

- Partial coatings or masking are also possible.

- Different chrome-effect lacquers create individual colour nuances.

A business worth millions.

The design process involves the precise coordination of colours, materials and surfaces to create functional and aesthetic products. Careful selection and innovative techniques are used to create surfaces that both strengthen the brand identity and influence perception and the user experience.