https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.

https://www.silcos.com/wp-content/uploads/2025/03/sic_website_blogbeitrag_klimafit_3.jpg

1463

2400

dwkadmin

https://www.silcos.com/wp-content/uploads/2023/10/silcos-sity-logo.png

dwkadmin2025-03-04 16:33:302025-04-01 13:54:53Karma is a b*tch.Over-moulding of inserts

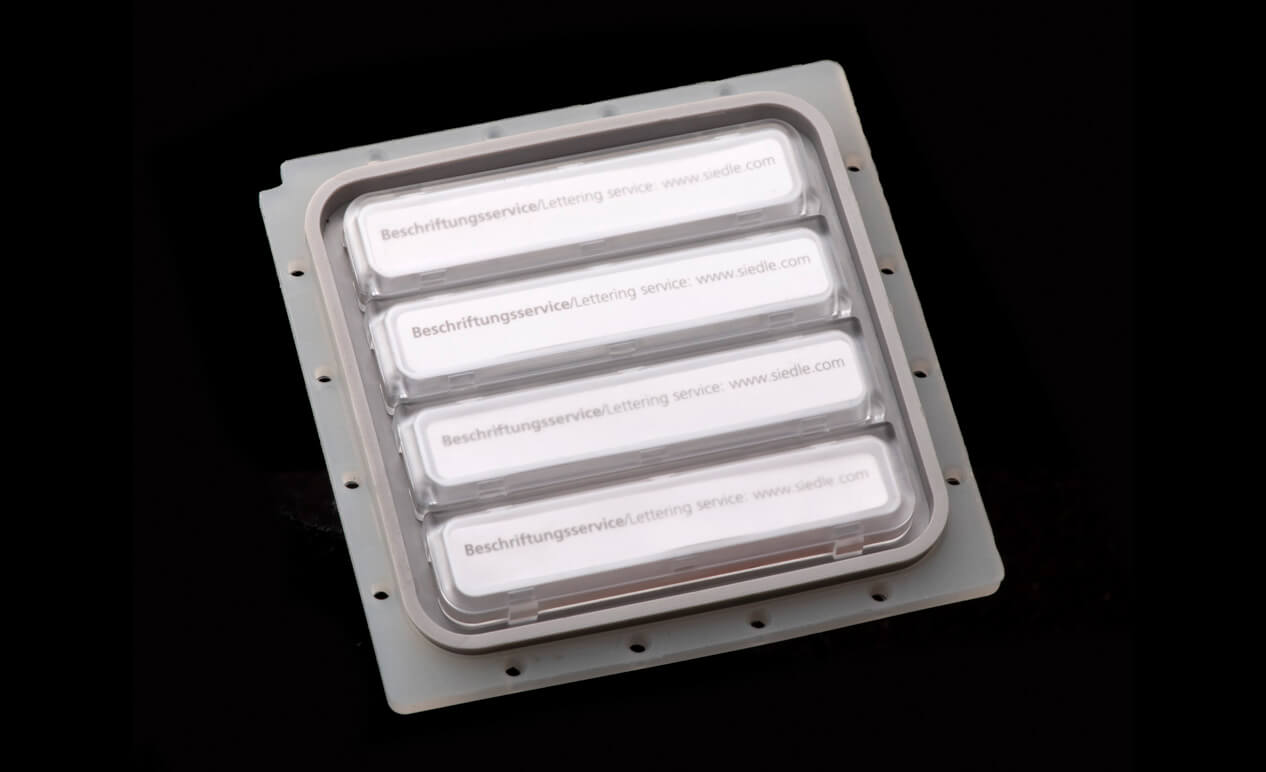

The combination of silicone with other materials allows additional design freedom for the designer and cost savings during assembly. In addition to plastics, metals, magnets and printed circuit boards are also suitable for over-moulding with silicone.

Our 2K silicone moulded parts are versatile and can be used in a variety of areas. The ever-increasing number of wearables and smart devices requires the integration of sensors, magnetic actuators or even circuit boards in flexible silicone housings. The possibilities for multi-component moulded parts are many and varied, including for connectors and control panel applications, for example.

As a complete solution provider, Silcos offers you the entire process chain, from feasibility studies to mould production and series production. Over-moulding of components provided by you, such as sensors or circuit boards, is also possible.

If required, we can then enhance the products for you in terms of feel or appearance using our surface processes.

Over-moulding of inserts at a glance

- Over-moulding of plastics, metals, magnets and printed circuit boards

- Flexible silicone housing

- Resilient, even for robust applications

- Over-moulding of components provided by the customer

- Surface processes on demand

Series production – superlative quality in series

We act as a system provider and manage assemblies from the task definition and prototype through to series production.

- Many years of experience and expertise in series production

- Maximum quality standards

- Integrated continuous improvement process (CIP)

- Regular verification of the entire process chain

We support our customers in all phases of series production development and throughout the entire product life cycle.

A business worth millions.

The design process involves the precise coordination of colours, materials and surfaces to create functional and aesthetic products. Careful selection and innovative techniques are used to create surfaces that both strengthen the brand identity and influence perception and the user experience.